Our Products

Water Treatment Plants

Water treatment is, collectively, the industrial-scale processes that makes water more acceptable for an end-use, which may be drinking, industry, or medicine. Water treatment is unlike portable water purification that campers and other people in wilderness areas practice. Water treatment should remove existing water contaminants or so reduce their concentration that their water becomes fit for its desired end-use, which may be safely returning used water to the environment.

The term "water treatment" generally refers to potable water production from raw water, whereas "wastewater treatment" refers to the treatment of polluted water, where the pollution could be from human waste, industry, agricultural waste or other sources of pollution.

The processes involved in treating water for drinking purposes to provide a safe source of water supply may be solids separation using physical processes such as settling and filtration, and chemical processes such as disinfection and coagulation. Water purification is the removal of contaminants from untreated water to produce drinking water that is pure enough for the most critical of its intended uses, usually for human consumption. Substances that are removed during the process of drinking water treatment include suspended solids, bacteria, algae, viruses, fungi, minerals such as iron, manganese and sulfur, and other chemical pollutants such as fertilisers.

Measures taken to ensure water quality not only relate to the treatment of the water, but to its conveyance and distribution after treatment as well. It is therefore common practice to have residual disinfectants in the treated water in order to kill any bacteriological contamination during distribution.

Softning Plants

We are manufacturing and supplying water softening plants which use ion exchange resin.

Water softeners are specific ion exchanger’s equipments. Softening plant is used to soften the water, by removing the minerals that cause the water to be hard. Minerals like calcium and magnesium present in the water in their carbonates and bi-carbonates form makes the water hard which creates many problems when it is used in industrial as well as in other domestic purposes. The ion exchange is a process in which undesirable ions are exchanged for more desirable irons.

Water softening plant uses Ion Exchange process which relies on the replacement of the Calcium and Magnesium ions present in the water by an equivalent number of Sodium ions. This eliminates the unwanted characteristics of hard water because the sodium salts never forms scale in any of the machinery parts. The resins get charged by sodium chloride solution (common salt) which is the cost effective and easiest maintenance process. Pure Drops offers water softening systems in various sizes for home, restaurant and many more industrial applications.

This water softening plant removes all the impurities and hardness present in the water and makes it soft and skin friendly. The features are as follows:

- Automatic regeneration

- User friendly

- Require less space

Reverse Osmosis (RO) Plants

Reverse osmosis (RO) is a water purification technology that uses a semipermeable membrane to remove larger particles from drinking water. In reverse osmosis, an applied pressure is used to overcome osmotic pressure, a colligative property, that is driven by chemical potential, a thermodynamic parameter. Reverse osmosis can remove many types of molecules and ions from solutions, including bacteria, and is used in both industrial processes and the production of potable water. The result is that the solute is retained on the pressurized side of the membrane and the pure solvent is allowed to pass to the other side. To be "selective", this membrane should not allow large molecules or ions through the pores (holes), but should allow smaller components of the solution (such as the solvent) to pass freely.

A reverse osmosis plant is a manufacturing plant where the process of reverse osmosis takes place. An average modern reverse osmosis plant needs six kilowatt-hours of electricity to desalinate one cubic metre of water. The process also results in an amount of salty briny waste. The challenge for these plants is to find ways to reduce energy consumption, use sustainable energy sources, improve the process of desalination and to innovate in the area of waste management to deal with the waste. Self-contained water treatment plants using reverse osmosis, called reverse osmosis water purification units.

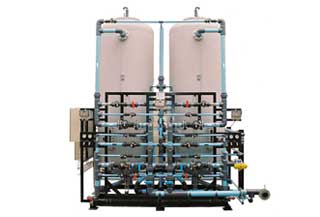

Demineralizing (DM) Plants

Demineralization or D.M. plants help to remove dissolved minerals from water to make it suitable for industrial and commercial use. The demineralization process is also known as De-Ionization.

De-mineralization technology is the proven process for treatment of water. A DM Water System produces mineral free water by operating on the principles of ion exchange, Degasification, and polishing. Demineralized Water System finds wide application in the field of steam, power, process, and cooling.We offer DM water plants, which are most effective in terms of both action and cost. These DM water plant uses various effective processes to clean the water and make it safe and hygienic.

Operating Principle: Raw water is passed via two small polystyrene bead filled (ion exchange resins) beds. While the cations get exchanged with hydrogen ions in first bed, the anions are exchanged with hydroxyl ions, in the second one.

Below are the features of DM Plants:

- Variety of cost effective standard models

- Improved aesthetics and rugged design

- User friendly, low maintenance and easy to install

- Simpler distribution and collection systems

- Quick availability

- Pre dispatch assembly check

Mixed Bed Polisher

The ion exchange process in a mixed bed filter does chemically work as described under demineralisation. However, the mixed bed filter is filled with both strongly acidic and strongly alkaline ion exchange resin at the same time. During operation, the different resin types are mixed with eached other. This basically works like a series of many small connected cation and anion exchangers, and thus results in a very high demineralisation effect.

For regeneration, the resins are first seperated with water, by making use of their different specific weights. The strongly acidic cation exchange resin is regenerated upstream with acid, the strongly alkaline anion exchange resin is regenerated downstream with acid. The regeneration effluent is drained from the transitional region between the two resin types. Often, the effluent contains an excess of acid or lye, and accordingly needs to be neutralised before being discharged into the sewer system. After regeneration, air is used to intermix the two resin types with each other again.

Compared to other ion exchange processes, the amount of excess chemicals required for regeneration of a mixed bed filter is significantly higher. That is why a mixed bed filter is usually only used for polishing, for example of already demineralised water or condensante, with an accordingly long service life between regenerations.

Pressure Sand Filter

The water naturally contains dissolved and Undissolved impurities. Undissolved impurities of water and precipitate sludge can be removed with the mostly popular and basic treatment of filtration. Various types of Aquaion filtration plants are available for different type of impurities to be removed with different flow rate.

Aquaion filters are made from mild still/FRP closed vessel incorporating frontal piping fitted with valves and are operated under pressure. The water is passed through the filter from different grade of filter media, where unwanted impurities are left behind at the filter bed. Filter have back flushing arrangement, which very easily flushes away the deposited impurity at filter bed to cleans the filter bed, thus reverse flow of water flushes away the impurities deposited at filter bed.

Activated Carbon Filter

The primer treated effluent water contains dissolved and Undissolved impurities. Undissolved impurities can be removed suitable filtration plant but it cannot remove dissolved organic/inorganic impurity i.e. color,odor,cod,bod etc.. which required to remove for particular level by activated carbon filtration column.

Activated carbon filters are made from mild still/FRP closed vessel incorporating frontal piping fitted with valves and are operated under pressure. The water is passed through the under bed media & granuler activated carbon layer. Where the carbon granule at certain level absorbs unwanted impurities for removal of free chlorine, phenol, taste and odor as well as reduction COD/BOD etc.

Carbon filter have back flushing arrangement, which very easily flushes away the deposited impurity at carbon granules. thus the reverse flow of water ,flushes away the impurities deposited at carbon granules. Activated Carbon Filter, for removal of free chlorine, phenol, taste and odor as well as reduction COD/BOD.Water Treatment Chemicals

For the chemical treatment of water a great variety of chemicals can be applied.

Advanced, scientifically formulated water treatment chemicals manufactured to the highest international quality and environmental standards for guaranteed performance. Water treatment products are used in many commercial, municipal and industrial process environments to improve productivity, optimise performance and reduce life-cycle costs.

Boiler Water Chemicals

We bring forth a wide range of Boiler Water Treatment Chemicals that are formulated from quality raw materials. Our Experts duly test the Boiler Water Treatment Chemicals that we Manufacture, Export, and Supply. We carefully package our Boiler Water Treatment Chemicals so that they could retain their optimum physical and chemical properties.

- Boiler Water Treatment Chemical (VCHEM 101)

Boiler Water Treatment Chemical (VCHEM 101) is a sludge conditioner based on low molecular weight copolymer. This synthetic polymer is designed to produce light finely divided particles which are non adherent and easily removed in blowdown.

- Boiler Water Treatment Chemical (VCHEM 110)

We formulate Boiler Water Treatment Chemical (VCHEM 110) from quality materials. Effective against the sludge formed inside the Boiler drum, this (VCHEM 110) is a combination of phosphates with polymeric organic compounds. Our VCHEM-110 avoids crystallization of scale forming compounds. Our (VCHEM 110) forms magnesium hydroxide and calcium phosphate with magnesium ions and calcium ions.

- Boiler Water Treatment Chemical (VCHEM 115)

The Boiler Water Treatment Chemical (VCHEM 115) Oxygen Scavanger that we offer is a combination of various chemicals in the form of a crystalline powder. Our Boiler Water Treatment Chemical (VCHEM 115) Oxygen Scavanger searches the dissolved oxygen from the boiler-feed water. This (VCHEM 115) Oxygen Scavanger provides protection to the boiler.

- Boiler Water Treatment Chemical (VCHEM 120)

We offer a premium Boiler Water Treatment Chemical (VCHEM 120) PH Booster that has form of a crystalline liquid. Boiler Water Treatment Chemical (VCHEM 120) PH Booster acts immediately to maintain the alkalinity inside the boiler-feed water. Being a catalyzed ph booster, it removes acidity from boiler-feed water.

Cooling Water Chemicals

We are a trusted Manufacturer, Exporter, and Supplier of high grade Cooling Water Treatment Chemicals. Duly tested by experts before the dispatch, our Cooling Water Treatment Chemicals assure a reliable performance. Our Cooling Water Treatment Chemicals are formulated from quality materials. We package our Cooling Water Treatment Chemical hygienically.

- Cooling Water Treatment Chemical (VCHEM 104)

Cooling Water Treatment Chemical (VCHEM 104) is a blend of organic and inorganic scale and corrosion inhibitor. The product is stable over a wide range of temperature and pH variation and provide scale and corrosion control over wide range of water qualities and operational condition.

- Cooling Water Treatment Chemical (VCHEM 105)

We offer a premium Cooling Water Treatment Chemical (VCHEM 105) that has form of a crystalline liquid. This Cooling Water Treatment Chemical (VCHEM 105) PH alkalinity STABILIZER acts immediately to maintain the alkalinity inside the cooling water system. Being a catalyzed pH booster, it removes acidity from boiler-feed water.

- Cooling Water Treatment Chemical (VCHEM 106)

Our Cooling Water Treatment Chemical (VCHEM 106) Micobicide has an ability of VCHEM-106 Micobicide to control the growth of microorganisms effectively. It combines with the cell wall and cytoplasmic membrane and after adsorption and infiltration of the cytoplasmic membrane forms colloidal solution with the cytoplasm and precipitates protein.

Effluent Treatment Chemicals

We also design effluent treatment and sewage treatment plants and water pollution control related equipments. We are designing and manufacturing fixed and floating aerators, clarifier, clariflocculations, thickners, agitators, mixers, stirrers, flocculators, oil skimmers, mechanised bar screen etc. for sewage treatment plant and wastewater treatment plant.

The effluent treatment plants are designed to treat the effluent coming from different areas of the plant. The treatment of different effluents varies with the type of effluent. Water effluent treatment systems are designed to treat effluent mainly containing oily effluent. The water from the transformer area, turbine building, workshop etc. , is collected in common collection sump from where water is pumped through the plate interceptor.

With the increase in the number industries, there is an increment of compounds of heavy metals and synthesized organic compounds into water causing its pollution. It is adding some 10,000 new organic compounds each year. Our company holds great reputation in the market as a manufacturer, supplier, and exporter of flawless effluent treatment plants (ETP). We have over a decade of experience in making and exporting effluent water treatment plants. These etps are based on cutting-edge technology.

Further, with the technological changes in manufacturing process has resulted into more addition of compounds discharge. Conventional waste water treatment process is not efficient to treat the polluted water. With this thought in mind, eco-chem laboratories p ltd offers top-quality industrial effluent treatment plants which are highly appreciated by our clients for their effectiveness, easy handling, less maintenance, and affordable prices.

Operation: Our effluent treatment plant and system is based on the aerobic respiration method; it consists of three stages namely primary treatment, secondary bio-treatment, and tertiary treatment. The effluent water is passed through various processes such as chemical dosing, aeration, and settling. The final treatment filtration cum absorption takes place by filters. Finally, the processed water goes for advance treatment and we get usable water which can be used further for irrigation and other purposes.

RO Antiscalent

Reverse Osmosis Antiscalant are a family of chemical designed to inhibit the formation and precipitation of crystallized mineral salts that form scale. Our Antiscalant for Reverse Osmosis are highly effective in controlling the deposit of inorganic scale foaming salts and particulate fouling on membrane surfaces.

Use of our Reverse Osmosis Antiscalant save money by protecting expensive membranes, reduces use of acid for cleaning, high recovery rate, reduce energy cost, save downtime in frequent membrane cleanings. Our Antiscalant for RO is cost effective and prevent mineral scaling of your membranes. Following are Antiscalant for Reverse Osmosis system.

RO Cleaning Chemicals

Reverse Osmosis membranes and other membrane systems need periodic cleaning and servicing. For optimal performance specific chemicals are required, depending on the cause of the pollution.

Membrane Fouling and Scaling

The concentration of all materials in the feed water - dissolved and suspended - is highest near the membrane surface. As permeate is removed through the membrane, all impurities are left behind near the membrane surface. The layer of water next to the membrane surface (boundary layer) gets more and more concentrated in the dissolved and suspended materials. These concentrations reach a certain steady level depending on feed velocity, element recovery and membrane permeate flux (gallons per square foot of permeate produced per day).

It is important to follow membrane manufacturers' recommendations on minimum feed flow, maximum element recovery and maximum element flux. These recommendations are based on the element size and quality of feed water being treated. The concentrations of the dissolved and suspended solids in the boundary layer control the performance of the membrane. Higher concentrations mean higher osmotic pressure, higher tendency of suspended solids to coagulate and coat the membrane surface, and higher likelihood of scaling to take place. Maintaining proper operating conditions for the membrane is the key preventative step to minimize membrane fouling.

The processes that are mentioned above will cause a decrease in capacity and/or an increase of the pressure and, as a result, of the energy use.

It is very important to purify the membrane preventively. In many cases regular mild cleaning is better than cleaning periodically with an aggressive cleaning product. The membrane will than last longer.

Sugar Industries Chemicals

PAT offers a range of speciality sugar chemicals. Our range includes organic and inorganic antiscalants, biocides and sugar juice clarifications.

Sugar Mill Sanitation Biocides

This chemical is a caramate based microbiocide specially formulated to inhibit growth of bacteria and fungi in cane sugar mills.

Carbon filter have back flushing arrangement, which very easily flushes away the deposited impurity at carbon granules. thus the reverse flow of water ,flushes away the impurities deposited at carbon granules.

These chemicals are highly effective against acid producing bacterial and fungi found in sugar mills. It also improves sugar recovery from stored sugar by reducing bacterial sugar inversion. It also inhibits enzyme action for the time between crushing of cane and lime neutralisation.